Mushroom Tray Packing Machine

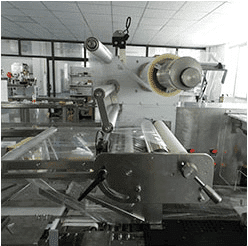

Mushroom tray packing machine can automatically complete the supply of materials and packing materials, wrapping, sealing, and cutting off the finished product. On-line production can be optional configuration: intelligent identification, weighing, printing price bar code, finished product delivery, product trace ability, date batch number, data output and other processes, Changing product specifications is convenient and quick to adjust for the mushroom packing machine. The programmable controller is used to program the operation data of the whole mushroom tray packing machine, and the sealing of the package is flat, the embossing is clear, safe and hygienic, fresh and beautiful.

When the sensor can’t detect the tray, the mushroom packing machine will stop the seal and wait for the conveyor belt to feed, no empty bags are made to avoid unnecessary waste of packing film.

When the sensor detects a product misalignment, the device will automatically skip the product and cut when the next product arrives. This not only avoids the loss of the product being cut, but also avoids the damage of the sealing tool, thereby reducing the failure rate and extending the life of the mushroom packing machine.

When the sensor detects that there is something else or the product has been cut, the system will determine whether the item has been cut, and it will immediately return to the origin and stop.

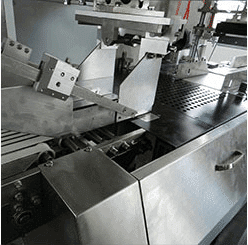

The baffle made of stainless steel and the belt that can be disassembled for washing, pay attention to the safety and sanitation of the machine.

Print price barcode, product traceability, data batch number, data output and other processes.

Changing product specifications is convenient and quick to adjust, input length system to meet the needs of different materials.

Application video of the mushroom packaging machine

Mushroom Packing Machine – specification

| Model | SMTP-500S |

| Dimension | L3580 X W975 X H1600(mm) |

| Packing capacity | 10 – 60(pcs/minute) |

| Maximum film speed | 20 (m/minute) |

| Maximum film width | 500(mm) |

| Maximum film diameter | 300(mm) |

| Packing product size(height) | 130(mm) |

| Packing product size(width) | 200(mm) |

| Packing cutting size | >90mm All of the above can be sealed and cut |

| Electric capacity | 220V/5(KVA) |

| Weight of machine | 620(kg) |

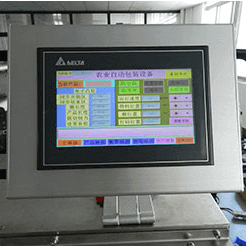

| Dimension | DELTA |

| Servo motor | DELTA |

| Frequency converter | DELTA |

| Temperature Controller | OMRON |

| Photoelectric eye | KEYENCE |

PRODUCT PERFORMANCE:

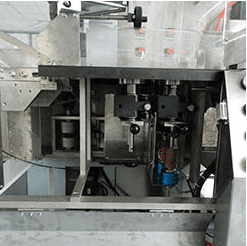

1: Adopt reciprocating head sealing to extend the sealing time to ensure a better and more beautiful sealing effect.

2: Adopt three-sided sponge compressed air to achieve the exhaust effect required by Flammulina velutipes packing.

3: The size of the mushroom packing machine is simplified, which is convenient for users to arrange the position of the machine reasonably.

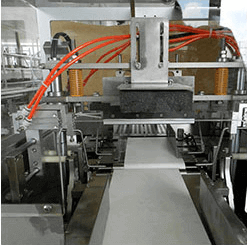

4: In order to better realize the stability of the packing machine and the adjustment ability of the machine itself, a total of 2 axis servo motors are installed in each driving part, the automatic adjustment function is used inside, and the error accuracy is reduced to about 1mm.

5: The handle can be used to easily adjust the tension between the driving roller and the heating roller of the middle sealing part.

6: Up to 30 varieties of product information can be retained in the touch screen, realizing a multi-variety and low-volume production mode.

7: The supply conveyor belt adopts stainless steel baffle plates and a belt that can be removed for washing at will, pay attention to the safety and sanitation of the machine.

8: The surface maintenance of the sealing part of the packing machine and the cleaning of waste materials generated during product packing can also be performed easily.